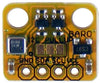

The Kit Eleven is a Freetronics Eleven with all the surface mount parts already in place, and a small number of through-hole parts for you to solder to the PCB. Even if you have no previous experience with electronics you should be able to get through it by following this guide.

Note: this guide does not teach you how to solder. If you've never soldered before, please see www.freetronics.com/how-to-solder.

Step 1: Check / Identify Required Parts

| Part | Qty | Description |

|

2 | 16MHz crystal |

|

1 | 2x3 pin header |

|

1 | 2.1mm PCB-mount DC jack |

|

1 | 1x6 female header |

|

2 | 1x8 female header |

|

1 | 1x10 female header |

|

1 | Atmel ATmega328P MCU |

|

1 | 28-pin DIP IC socket |

|

1 | "Eleven" PCB with SMT parts fitted |

Step 2: Crystals

A good general principle is to fit the lowest parts first. The smallest parts are the 16MHz crystals. They are not polarised, so it doesn't matter which way around you insert them.

Insert the crystals as shown in the photo below.

Alternatively you can use Blu-Tack or similar to hold the body of the crystal in place.

Try not to use excessive heat on the crystals. Work smoothly, and apply just enough heat to make a good joint.

After the leads are soldered, trim off the excess length with side cutters.

Step 3: IC socket

The 28-pin IC socket itself isn't technically polarised, but it's important to get it around the right way because it includes a little indicator notch that shows how the IC should be plugged in. You'll see one end of the socket has a small notch in it to indicate which end is pin 1. The PCB overlay also shows the ends of the socket, with one end straight and one end notched. Match the notches together, insert the socket, and solder it in place.

In the photo below, the notch is to the right.

It may tend to want to fall out while you're trying to solder it, so you may find it handy to use a bit of tape or Blu-tack to hold it down until you've soldered at least a few pins on.

Step 4: ICSP Header

The ICSP header is the 2x3 pin header (6 pins total) that fits on the right side of the PCB as shown below.

The little plastic spacer is closer to one end of the pins, so they are short on one side and long on the other. The short end goes through the PCB, and the long end sticks up.

Soldering pin headers is a great way to burn your fingers because the heat travels straight up through them, so you may want to resort to tape or Blu-Tack to hold them while soldering.

Step 5: Female Headers

By this point you'll be an expert, but be careful: fitting the 1x6, 1x8, and 1x10 female headers into position on the edges of the PCB is not quite as simple as you may think. It's surprisingly hard to get them straight, and if you don't get them properly aligned it can be hard to fit a shield on top.

A handy trick for soldering the female headers is to use a shield as a jig to hold them in place. If you have a shield, plug the loose headers onto the shield pins and then fit them onto the PCB. The shield will hold them straight while you solder them on. Then when you have finished soldering, you just remove the shield and you'll have perfectly aligned headers on your Eleven.

Step 6: Power Jack

The 2.1mm DC jack goes into position on the bottom left of the PCB. You may find that you need to apply your soldering iron for a while before the solder will flow properly, because the heat will quickly conduct through the large copper area of the PCB.

Step 7: MCU

You're almost done! Just the MCU to go.

Try not to handle the pins too much once you remove the MCU from the foam.

The MCU must be installed the right way around, and if you look carefully at the ends of the body you'll see that one of them has a small notch in the plastic. Once again that's the end near pin 1, and it has to align with the notch in the IC socket. If you have your Eleven oriented like in the photo above, the notch needs to be on the right. If we've done our job properly the MCU sticker should end facing you, but don't just trust the sticker: always look at the body of the MCU to check that you know which end is which.

When you try to insert the MCU into the socket you'll probably find (frustratingly!) that the MCU pins spread out slightly and won't fit in. To make the pins fit you can put the MCU down sideways on your workbench and push down on it firmly while holding the ends, bending the legs in until they're a bit straighter. Do it evenly on both sides and you should be able to push the MCU down into the socket until it seats properly.

Finally, do a quick visual inspection of the MCU to make sure that no stray pins ended up bent out sideways and missed the IC socket. If there are, use a small screwdriver or similar to lever the chip out of the socket evenly from the ends, bend the pins into place, and try again.

Once you're happy with that, do a broader visual inspection of the whole board. Look for solder bridges between pins, bits of cut-off component leads, or anything else that seems out of the ordinary.

Step 8: Power Up

Connect the Eleven to your computer using a micro USB cable, and start the Arduino IDE. Select the correct serial port, set the board type to "Arduino Uno", and have fun playing with your new Eleven!

See the Eleven page for more resources, drivers, and other guides.