We figure that there are a huge number of people out there who have the ability to design projects that could potentially be turned into retail products, but who don’t know what to do once the prototype is done. Creating a prototype or two on your workbench is a long way from having it available over the shelf in a local electronics store, and the steps required to go from breadboard to retail display cabinet can be daunting. You need to consider things like:

- Production design-rule (DR) checks.

- PCB manufacturing.

- Automated parts assembly and soldering.

- Retail packaging.

- Documentation and instructions.

- Warehousing and distribution.

- Retail sales channel agreements.

- Warranty claims.

Our objective in setting up Freetronics is to use our contacts and experience with electronics manufacturing to give Open Hardware designers an opportunity to have their designs hit “the big time”, displayed in national retail chains and sold online as finished products. To make that happen we’re doing something a bit unusual: we’re taking the book publishing business model and applying it to electronics manufacturing.

Think about what happens when an author and a publishing company works together. The author presents a manuscript to the publisher, who then edits it to prepare it for printing and generates final “production ready” files. The publishing company underwrites the production costs and then manages distribution of the printed books through their contacts with retail chains. When retailers buy the book they pay the publisher for it, who then pays royalties to the author.

All you have to do is re-read that description but replace the word “author” with “designer”, “publisher” with “Freetronics”, “printer” with “manufacturer”, and “book retailer” with “electronics retailer” and you have exactly the model that Freetronics operates under.

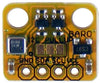

1. The designer provides a raw design to Freetronics. We apply design-rule checks, and apply our house design-style to give it the identifiable Freetronics look-and-feel with yellow PCB, rounded corners, top and bottom overlay, etc.

2. We generate production-ready Gerber files and supply them to our tried and tested manufacturing partners.

3. The professionally fabricated, assembled, and tested product is delivered to Freetronics.

4. Freetronics assembles any necessary packaging and documentation, and fulfills orders from direct retail customers and retail chains.

5. Electronics retailers and retail customers pay for the product.

6. Freetronics generates quarterly royalty statements and pays royalties to the designer.

It’s an interesting approach to electronics manufacturing and we’re hoping that it will give many talented Open Hardware designers an opportunity to get their projects out to the wider community and also make some money along the way. In any case we’re going to give it a red-hot go!

Got an idea for an Arduino project you’d like manufactured? Please get in touch!